Shop Applications

| |||||||

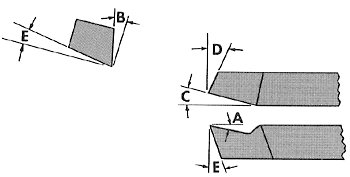

| Cutting Angles for Turning Tools | |||||

Nomenclature for Single Point Cutting Tools |  | ||||

Material Machined | A | B | C | D | E |

| Back Rake Angle | Side Rake Angle | Side Cutting Edge Angle | End Cutting Edge Angle | Front & Side Clearance Angle | |

Steel: Soft Steel: Medium Steel: Hard | 15 10 6-8 | 10-12 10 6 | 0-15 0-10 0-8 | 8-15 8-15 8-15 | 7 6 6 |

Stainless Steel: Soft Stainless Steel: Medium Stainless Steel: Hard | 0-15 0-10 0 | 15 10 8 | 0-15 0-15 0-15 | 8-15 8-15 8-15 | 7 7 7 |

Cast Iron Malleable Iron Cast Steel | 0 0-8 0-8 | 5 8-12 8 | 0-15 0-10 0-10 | 8-10 8-15 8-10 | 5-6 6 6 |

Aluminum Brass Bronze | 10-20 4 4 | 12-15 4 4 | 0-15 0-15 0-15 | 8-10 8-10 8-10 | 7-10 5-6 5-6 |

| Suggested Cutting Speeds for Screw Machine Work on Stainless Steel | |||||

Type Stainless Steel | Brinell Hardness Range | Roughing Cut | Finishing Cut | ||

| Cutting Speed | Feed In/Rev. | Cutting Speed | Feed In/Rev. | ||

302 303 304 | 150-185 150-180 150-185 | 90-130 90-150 90-130 | .005-.015 .005-.015 .005-.015 | 100-150 125-200 100-150 | .003-.005 .003-.005 .003-.005 |

309 316 321 | 150-185 150-185 150-185 | 90-130 90-130 90-130 | .005-.015 .005-.015 .005-.015 | 100-150 100-150 100-150 | .003-.005 .003-.005 .003-.005 |

347 403 410 | 150-185 200-240 250-320 | 90-130 100-130 80-105 | .005-.015 .005-.015 .005-.015 | 100-150 100-150 80-120 | .003-.005 .003-.005 .003-.005 |

416 420 430 | 200-240 180-235 170-230 | 100-150 80-100 100-135 | .005-.015 .005-.010 .005-.015 | 140-180 100-150 100-150 | .003-.005 .003-.005 .003-.005 |

431 440 446 | 250-280 200-265 175-240 | 90-180 60-80 100-135 | .005-.015 .005-.010 .005-.015 | 90-140 80-100 100-150 | .003-.005 .003-.005 .003-.005 |

| Cutting Fluid: Water soluble oils are satisfactory. Non-corrosive sulphur oils are recommended. For dry cutting reduce speed approximately 15% | |||||