Model 150 Self-Feeding Drill Units

Self-Feeding Drill Units

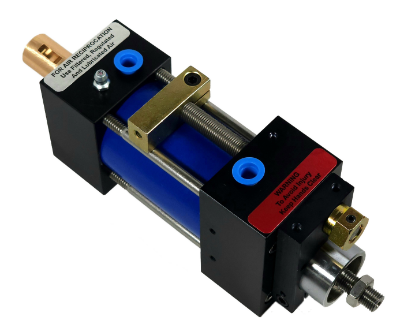

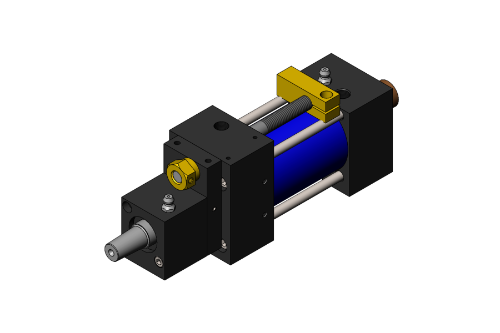

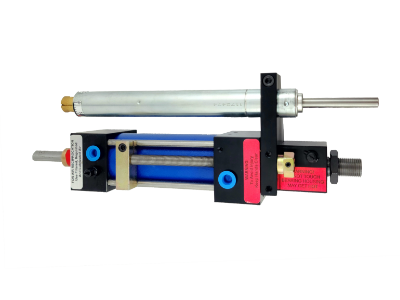

Pneumatic Stroke, Self-Feeding Drill Units

The model 150, 152, & 153 self-feeding drill units are automated self-feeding drills which can be actuated with air or oil. They are capable of producing thrusts of up to 182 lbs. with 100 psi air pressure and 364 lbs. with 200 psi oil pressure.

These units are usually used for drilling, reaming, boring and light milling applications, but can also be used whenever simultaneous rotary and linear motions are required. It can be mounted in any position, horizontal, vertical etc. As illustrated, it is supplied without a motor, but can be easily powered by an electric or air motor up to 1/3 hp. A simple pneumatic, or hydraulic control system is required to achieve forward and reverse stroke control. This can be purchased separately from Blackalloy™. See our Drill Unit Components reference page for a description of the customization options available.

Full product details

Drill Unit Options: The model 150 self-feeding drill unit can be equipped with the following options:

- No Feed Control - Model 150

- Feed Control -

- Model 152 Deep Hole (Peck) Drilling -

- Model 153 Self-Reversing Tapping Head Attachment -

- 3250 Tapping Heads Multiple Spindle Heads with Adjustable & Fixed Spacing

Depth Control: The stroke length of all Model 150, 152, & 153 self-feeding drill units can be controlled by a stop screw dial and nut which is fully adjustable from zero to the entire stroke range as ordered (1-1/2", 2", 3", 4", 6", & 8" Stroke Lengths). Depth control is achieved to within about .001" to .002" inch.

Lubrication: The internal seals of the drill unit must be lubricated with a light spindle oil to reduce friction and wear. A filter regulator and lubricator can be purchased from Blackalloy. Although the spindle and spline bushing are generously lubricated at the factory with grease, continuous use and hostile environments may require manual lubrication on a frequent, scheduled basis.

Drive Motors: Self-feeding drill units are usually powered by electric or air motors up to 1/3 HP and are usually belt driven through pulleys or driven directly through a flexible shaft coupling. The rear bearings are adequately sized to withstand normal pulley belt loads. However, over-tight belt tension may cause over loaded bearings and reduce bearing life.

Recommended Spare Parts: Normal wear items that may require replacement depending on length of service and operating conditions are all bearings and seals. These can be purchased as kits to keep on hand to reduce down time. For critical installations where down time must be minimized, a complete spare drill unit should be kept on hand.

Installation: Self-feeding drill units may be mounted in any attitude, i.e., horizontal, vertical or inclined as long as a sturdy and very flat support for both end blocks is provided, so as not to strain or distort the assembly. Three 1/4”-20 tapped holes are provided for mounting the unit, and a 1/4" dowel hole and 1/4" keyway are located in-line with the spindle, to facilitate line up and to insure exact repositioning. Flush out all chips and debris from air or oil lines before connecting to unit.

This degree of accuracy is not always possible with pneumatic reciprocation alone (Models 150 & 250) where the compressibility of air allows for variations in feed rates with changes in thrust load, particularly when breaking through a hole.

- Compact Sealed Oil Cylinder -- Low Cost

- Simple Cylinder Plunger Depression to Actuate Feed Control

- Controls a Segment or the Complete Drill Stroke Cycle -- 1/2", 1", 2", 3", 4" & 6"

- Adjustable Positioning Produces Rapid Advance Which Saves Cycle Time

- Suitable for Applications Requiring Forward Feed Control

- Right, Left or Top Mounted Feed Controls Available for Maximum Application Flexibility

- Top Mounted Feed Control Maintains 2" Minimum Centers for Multiple Unit Applications and Maximum Application Flexibility

- Minimum Feed Rate 0.2 In./Min.

- Maximum Feed Rate 240 In./Min.

Model 152 Drill Units with Feed Control Cylinders

| Stroke Lengths: |

1-1/2", 2", 3", 4", 6", & 8" | |

| Feed Control Lengths: | 1", 2", 3", 4", & 6" | |

| Spindle Extensions: | #1 Jacobs Taper | |

| Ø10mm (Ø.394") Round | ||

| 3/8-24 External Thread | ||

| Max Drill Size: | Ø1/4" in Steel | |

| Ø5/16" in Cast Iron | ||

| Ø3/8" in Aluminum, Wood & Plastic | ||

| Recommended Maximum RPM: | 3,600 RPM (5,000 w/ High Speed Bearings) | |

| Recommended Maximum HP: | 1/2 HP | |

| Maximum Operating Pressure: | 200 PSI | |

| Minimum Operating Pressure: | 20 PSI | |

| Cylinder Bore: | Ø1.75" | |

| Spindle Runout: | .0002" - .0003" | |

| Effective Stroke Area - Forward: | 1.82 in.² | |

| Effective Stroke Area - Reverse: | 1.19 in.² | |

| Thrust @ 100 PSI: | 182 lbs. | |

| Port Size: | 1/8" NPT | |

| Standard Pulley P.D. (Ø.750" Bore): | 1.75" ('3L' Belt) | |

| Maximum Ambient Temperature: | 150°F (65°C) |